Comparation with other models

Strengthening the effect of pulling tension , especially in PET film , better performance on glossness , pulling tension and adhesion since its higher solid content .

Please see the below compare table :

We keep 24 hours after lamination process .

Glossness : Based on 60°angles , better performance if figures is higher.

Pulling tension : Generally to speak , stronger pulling tension is a good sign for judging if adhesion is good or not , but it’s not always correct , another better way to judge adhesion is to check if pass “Die cutting” process.

Adhesion : To judging if paper and pp film are sticking together or not , tighter performance is better .

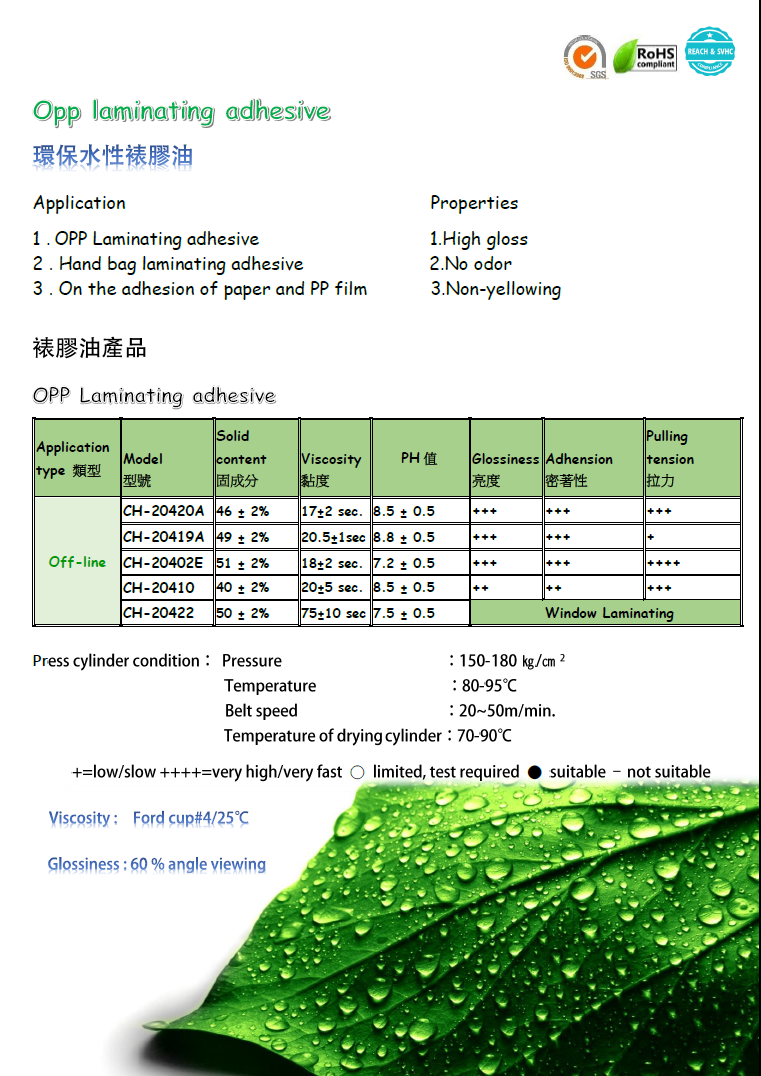

OPP Laminating adhesive

| Application type 類型 |

Model 型號 | Solid content 固成分 |

Viscosity 黏度 | PH值 |

Glossiness亮度 |

Adhension 密著性 | Pulling tension 拉力 |

| Off-line | CH-20420A | 46 ± 2% | 17±2 sec. | 8.5 ± 0.5 | +++ | +++ | +++ |

| CH-20420B | 47 ± 2% | 17±2 sec | 8.5 ± 0.5 | +++ | +++ | +++ | |

| CH-20402E | 51 ± 2% | 18±2 sec. | 7.2 ± 0.5 | +++ | +++ | ++++ | |

| CH-20410 | 42 ± 2% | 17±2 sec. | 8.5 ± 0.5 | ++ | ++ | +++ | |

|

|

|

|

|

| |||

FAQ

1.Q: Are you a factory or trading company?

A: Yes, we are one of the most professional manufacturers for overprinting varnish for printed paper substrates, includes different products line, Water based resin ,Solvent based resin, UV resin.

2.Q: How can I get some samples?

A: We are honored to offer you samples by express.

3 Q: How does your factory do regarding quality control?

A: Quality is the priority. We always pay much attention to quality control from beginning to end.

-----------------------------------------------------------------------

General questions for Water based resin

Q1: Why we can find the “White point” on surface ?

A: There are too many factors have lead to fail mirror surface , such as the paper too rough , varnish too thin , varnishing speed too high, too many powders when it printing , roller’s rubber too old to use…etc.

Solution: Please build the varnish up , slow down the speed and change the new rubber for operate more smoothly.

Q2 : Why not gloss after varnishing ?

A: Please raise up the temperature for iron board (more than 100 degree ) and pressure more than 125KG/CM2 , add up more varnish or change iron board for improving.

Q3: Blocking paper

A: Please keep down the temperature and slow down the varnishing speed to improve volatility too fast.

Q4: Why Ink spread out after varnishing ?

A: You can varnishing after confirm the ink already dry , change the solvent or keep down the pressure of varnishing machine.

Taiwantrade.com and iDealEZ.com uses analytical cookies and other tracking technologies to offer you the best possible user experience. By using our website, you acknowledge and agree to our cookie policy.

For more information on cookies or changing your cookies settings, read Taiwantrade & iDealEZ’s Privacy Policy.