Waterbased coatings

Waterbased coatings (also called dispersion coatings) dry physically by means of the absorption of the coating into the substrate and the evaporation of water. This drying is achieved through hot air and infrared. With the drying, water is extracted from the coating. The polymer particles approach each other and form the coating film. Waterbased coatings, as a result of their many advantages, have become the leading technology in the printing industry: environmentally friendly, odorless, tasteless, no yellowing and reduction of spray powder.

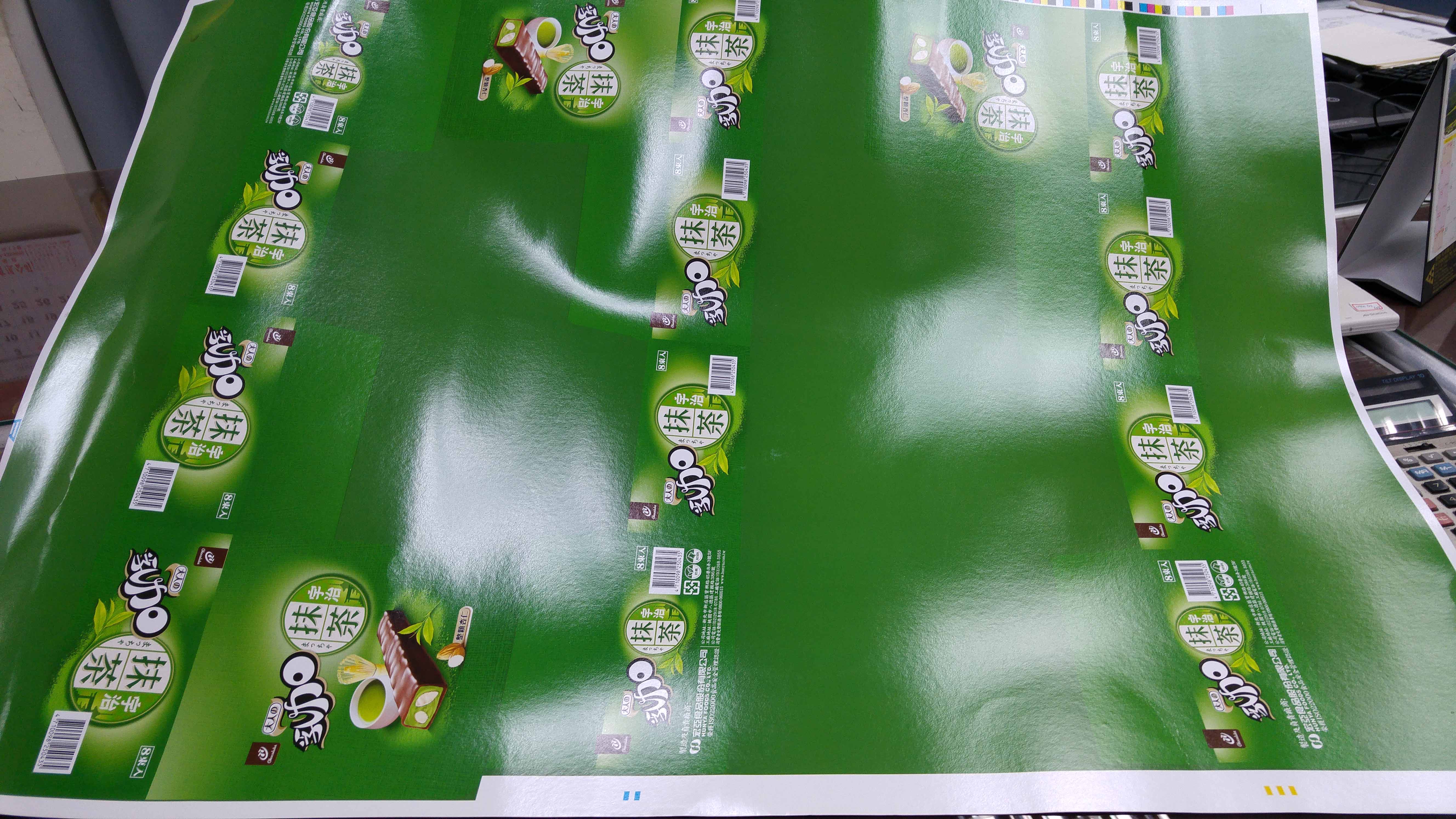

Chwen Shyang waterbased coatings are leading on the market due to their quality and strength in innovation. The high-performance recipes are continuously being developed to a high level. Employed extensively and proven in practice, TerraWet waterbased coatings offer excellent processing capabilities, particularly high application safety and conformity with legal regulations. TerraWet waterbased coatings are based on carefully selected and tested raw materials. Dispersions of acrylate and styrene acrylate polymers and alkaline-neutralized´resins form the basic framework of the coating. These components guarantee that the required coating film is formed. The correct filming between the substrate and the coating particles, as well as between the coating particles with respect to each other, is achieved by innovative wettingagents. High performance waxes provide for scuff resistance. Additives control properties in a defined way, such as for example foaming characteristics and slip properties. Finally the water takes over the function of the solution.

High solid matter

Suitable processing viscosity (adjusted to the coating application aggregate)

Stable viscosity

As frost resistant as possible

Film formation even at low temperatures

Need not be labelled

Biodegradable

Correct surface tension

Free of organic solvents

Odour free

No set-off in the pile

No blocking

No surface drying in the coating unit

Little foam formation

Good wetting of the substrate

Can be pumped

No use of powder if possible

Low consumption

Odour free

Easily cleaned

Gloss

Rub resistance

Blocking resistance (wet and dry)

Elasticity (Grooving and creasing ability)

Resistance to heat sealing

Odour free

Can be glued

Does not yellow

Slip

Clear films

Can be foil blocked

High film adhesion

Recyclable

Specification:

Composition :Emulsion of polyacrylate

Viscosity(Ford cup#4/25℃) :37.5 ± 2.5 sec.

Appearance :Milky white liquid

Solvent :Water

Solid content(%) :33 ± 3 %

pH :8.5 ± 0.5

Odor :Slight ammonia odor

1 .Water-base overprinting varnish

Application & Test:

1 .Process: CH-10117èPrint machine coater roller coating

èUse short wave inferred light(100℃/2sec)

2 .Film Special property:

(1)Good gloss

(2)Adhesion with printing ink

(3)Abrasion resistance

(4)Slip and Leveling

Shelf life :As for the shade, the shelf life of six months

FAQ

1.Q: Are you a factory or trading company?

A: Yes, we are one of the most professional manufacturers for overprinting varnish for printed paper substrates, includes different products line, Water based resin ,Solvent based resin, UV resin.

2.Q: How can I get some samples?

A: We are honored to offer you samples by express.

3 Q: How does your factory do regarding quality control?

A: Quality is the priority. We always pay much attention to quality control from beginning to end.

-----------------------------------------------------------------------

General questions for Water based resin

Q1: Why we can find the “White point” on surface ?

A: There are too many factors have lead to fail mirror surface , such as the paper too rough , varnish too thin , varnishing speed too high, too many powders when it printing , roller’s rubber too old to use…etc.

Solution: Please build the varnish up , slow down the speed and change the new rubber for operate more smoothly.

Q2 : Why not gloss after varnishing ?

A: Please raise up the temperature for iron board (more than 100 degree ) and pressure more than 125KG/CM2 , add up more varnish or change iron board for improving.

Q3: Blocking paper

A: Please keep down the temperature and slow down the varnishing speed to improve volatility too fast.

Q4: Why Ink spread out after varnishing ?

A: You can varnishing after confirm the ink already dry , change the solvent or keep down the pressure of varnishing machine.

Taiwantrade.com and iDealEZ.com uses analytical cookies and other tracking technologies to offer you the best possible user experience. By using our website, you acknowledge and agree to our cookie policy.

For more information on cookies or changing your cookies settings, read Taiwantrade & iDealEZ’s Privacy Policy.