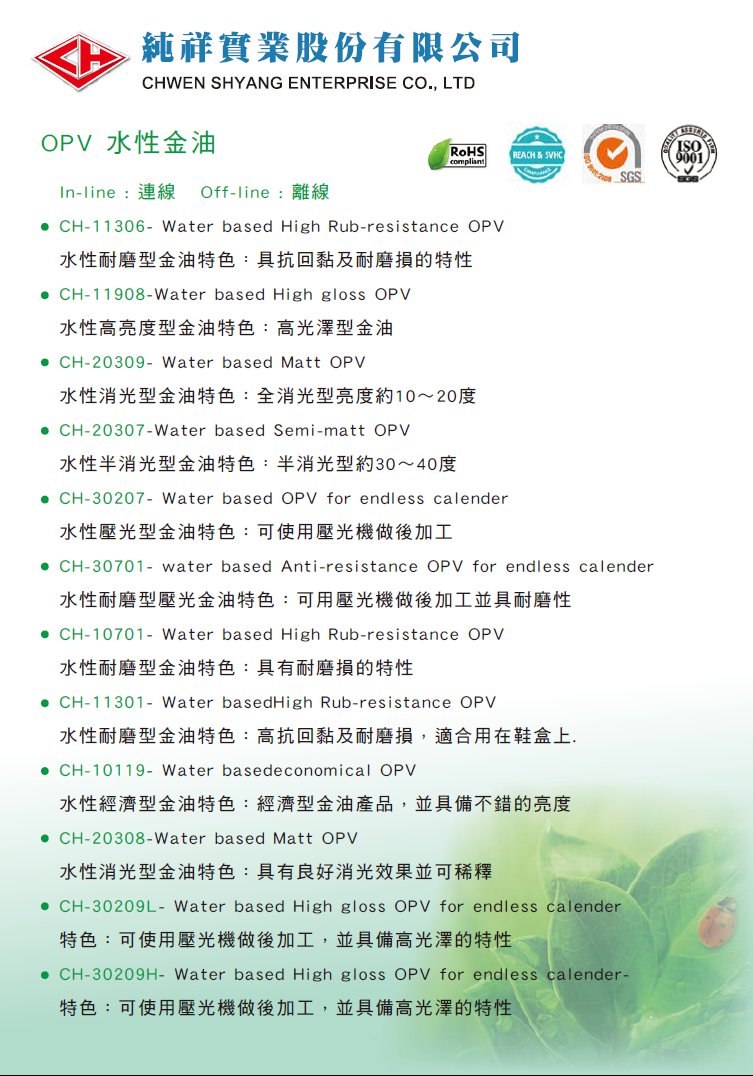

CH-30209L has best mirror effect on paper coating , easy to operate , suit for food packaging and cosmetics packaging .

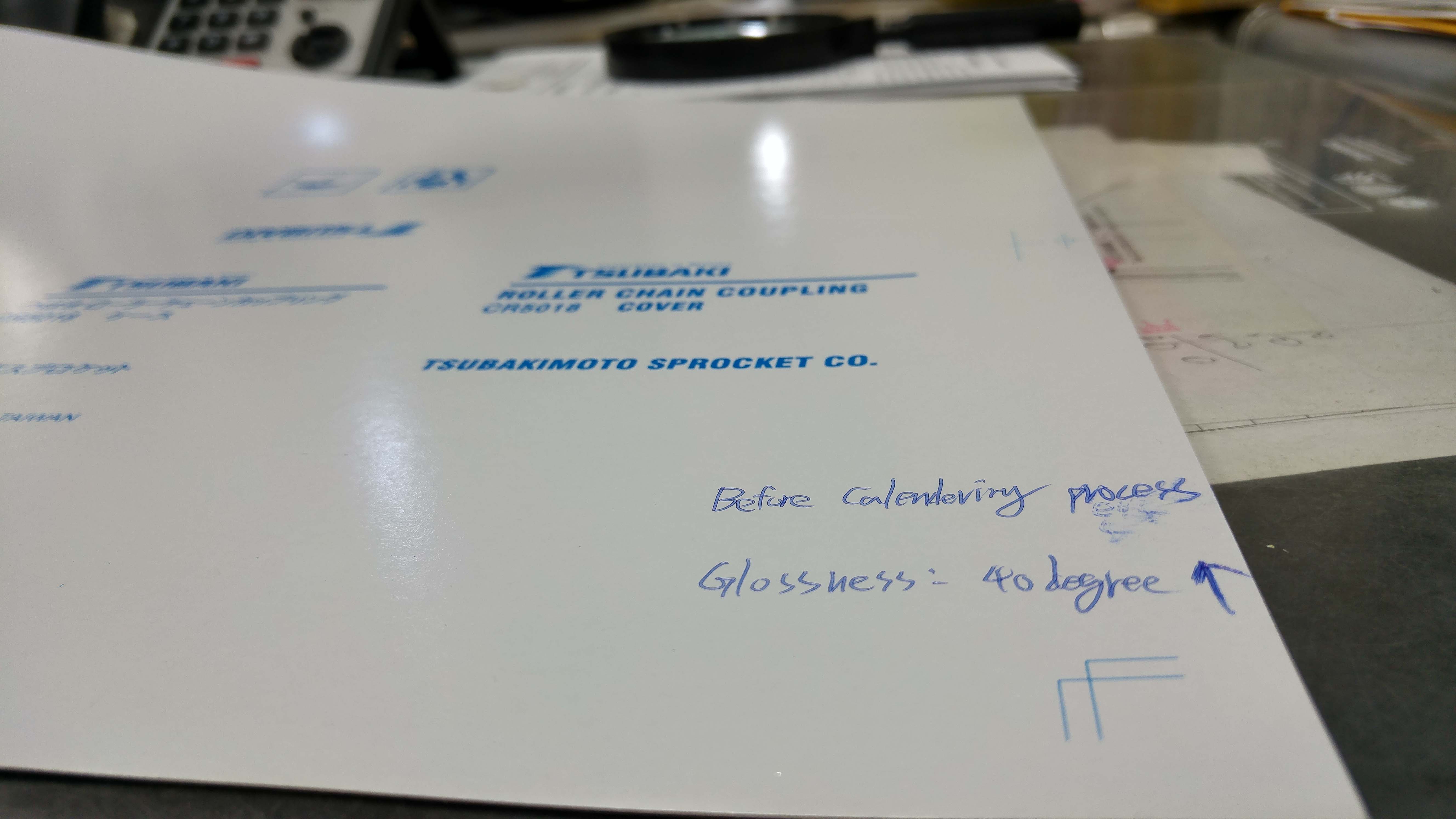

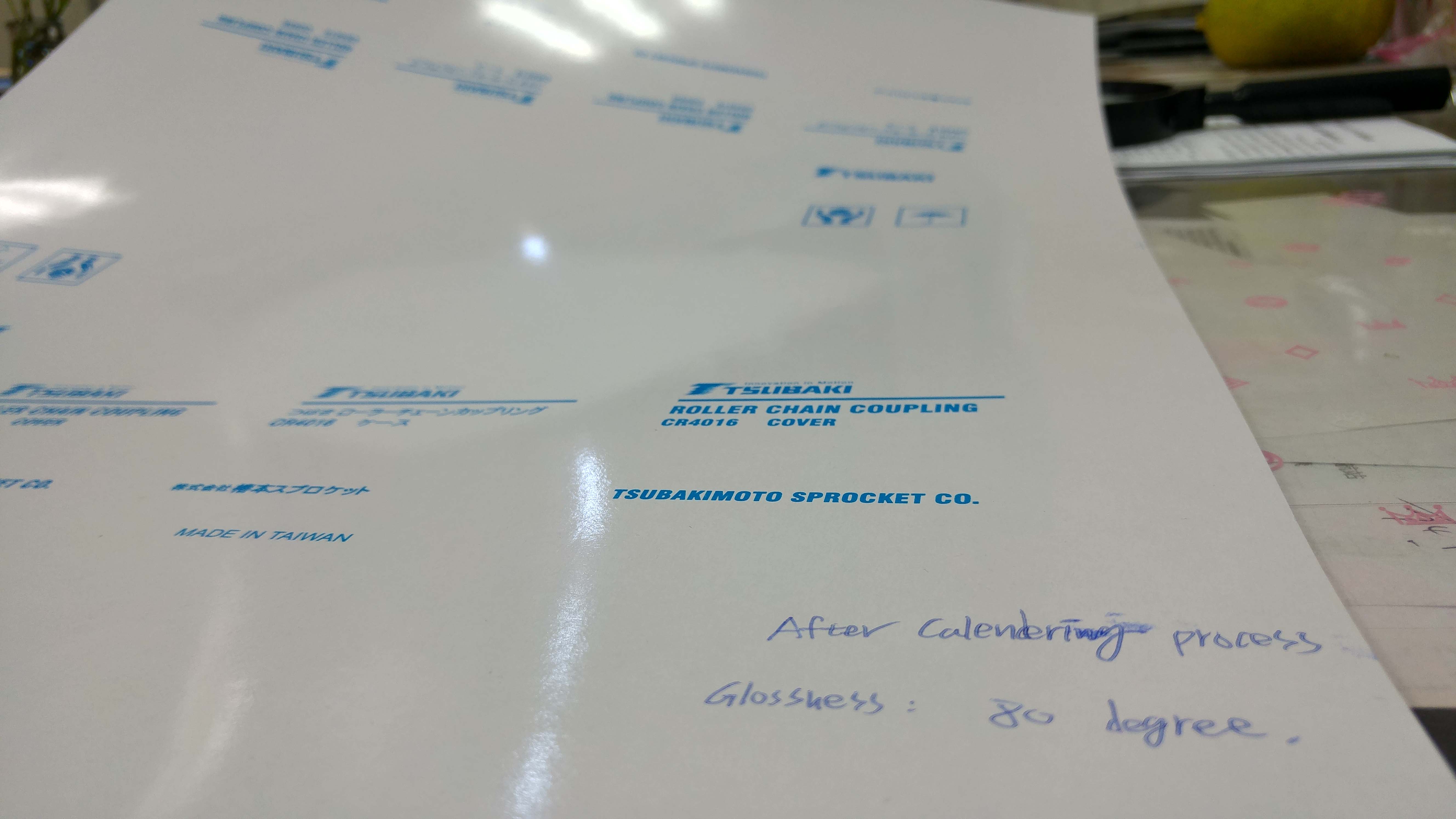

Calendering varnish is a kind of Water based varnish , general to say , it has better glossiness , anti-abrasion , flatness than normal Water based varnish , so Calendering varnish should be the highest glossiness and flatness from Water based varnish. Normally to say ,the degree of glossiness should be from 40~60 after coating process , Finishing product will reach glossiness from 80~90 after calendaring process.

During the calendering, the printed product runs through a calender in a subordinate production step. Between the heated calender cylinders (alternatively band calenders) the coating is melted. The surfaces are optimally polished by the simultaneously applied pressure. Through this smoothing, the coating develops the highest level of gloss.

Generally to speak , The ability of Rub-resistance should be from 200 to 500 times (4 pounds) , it’s better than normal Water based varnish , we also have High Rub-resistance calendering varnish CH-30701 which one we usually apply to Long-distance transport , such as Tissue box , Rub-resistance and Glossiness are very important for related Product.

Regarding the viscosity , it will be higher than normal Water based varnish since it need apply to calendering process , all in all , The results of calendering should be better if offer thicker coating on the paper . For the in-line printing machine, we suggest CH-30207 for applying to such thinner coating, high viscosity can help varnish not to be absorb too much by paper , We need select right viscosity for in-line application(75 sec Ford 4 cup) .

Press cylinder condition:Pressure :150-200㎏/㎝2

Temperature :95-110℃

Length of late: Longer then 10 Meter

The best Calendering temperature is 100℃ at least

Pressure not less than 125 ㎏/㎝2

Average coating thickness : 4~6 g/m2

In the case of rough paper , please thicker the coating layer .

Specification:

Composition :Emulsion of polyacrylate

Viscosity(Ford cup#4/25℃) :50 ± 5 sec.

Appearance :Milky yellow liquid

Solvent :Water

Solid content(%) :45 ± 3

pH :8.5 ± 0.5

Odor :Slight ammonia odor

End Use:

1 .Water-base overprinting varnish for endless calender

2 . Varnish for paper board

Application & Testing

1 .Process:

CH-30209H =>Varnish roller coater on printing machine

>Use short wave inferred light =>Press cylinder

Press cylinder condition:Pressure :150-200㎏/㎝2

Temperature :95-110℃

Length of late :Longer then 10 Meter

2 .Film Special property:

(1)Good gloss (4)Abrasion resistance

(2)Mold releasing (5)Adhesion with printing ink

(3)Fast drying (6)Non-yellowing

FAQ

1.Q: Are you a factory or trading company?

A: Yes, we are one of the most professional manufacturers for overprinting varnish for printed paper substrates, includes different products line, Water based resin ,Solvent based resin, UV resin.

2.Q: How can I get some samples?

A: We are honored to offer you samples by express.

3 Q: How does your factory do regarding quality control?

A: Quality is the priority. We always pay much attention to quality control from beginning to end.

-----------------------------------------------------------------------

General questions for Water based resin

Q1: Why we can find the “White point” on surface ?

A: There are too many factors have lead to fail mirror surface , such as the paper too rough , varnish too thin , varnishing speed too high, too many powders when it printing , roller’s rubber too old to use…etc.

Solution: Please build the varnish up , slow down the speed and change the new rubber for operate more smoothly.

Q2 : Why not gloss after varnishing ?

A: Please raise up the temperature for iron board (more than 100 degree ) and pressure more than 125KG/CM2 , add up more varnish or change iron board for improving.

Q3: Blocking paper

A: Please keep down the temperature and slow down the varnishing speed to improve volatility too fast.

Q4: Why Ink spread out after varnishing ?

A: You can varnishing after confirm the ink already dry , change the solvent or keep down the pressure of varnishing machine.

Taiwantrade.com and iDealEZ.com uses analytical cookies and other tracking technologies to offer you the best possible user experience. By using our website, you acknowledge and agree to our cookie policy.

For more information on cookies or changing your cookies settings, read Taiwantrade & iDealEZ’s Privacy Policy.